If you are anything like me, when it comes to choosing good quality faux leather, the excessive amounts of facts, certifications, rules, figures, tests and regulations being thrown at you is somewhat overwhelming, when all you simply require is a good quality faux leather. The key – knowing what to look for and listen to.

The three deciding factors:

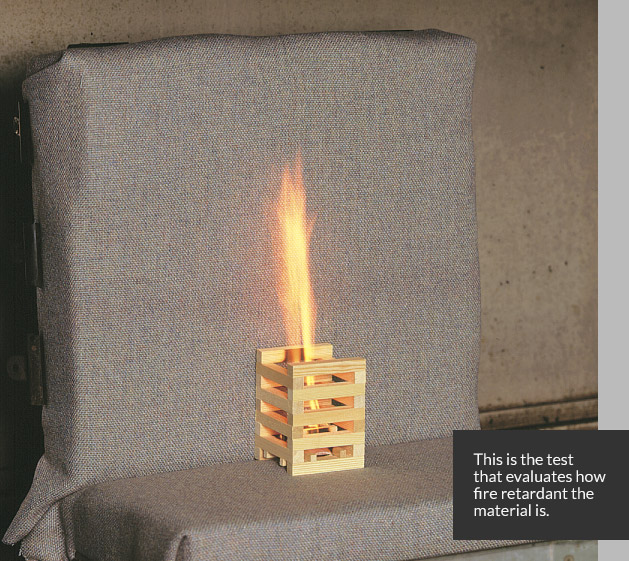

When it comes to the regulations, the key certificate you need to prove your faux leather is contract standard, is the CRIB5 certification. This is the test that evaluates how fire retardant the material is. The test is very simple yet effective, a certain amount of wood (the CRIB) is burned on the centre of the material until the wood has burnt out and turned to ash (please see the picture below). The material is then evaluated and assessed to see what damage has been caused or if the material has caught fire. The 5 in the certificate title is the amount of wood burned on the seat pad. This goes from a domestic standard of CRIB3, through to ultra-fire resistance of CRIB7. An example of the certificate seen in the link – Pages 5, 6, 7 and 8 – click here.

The Martindale Rub Test – arguable the single most significant test to show a faux leathers quality and durability. The test simulates natural wear of a seat cover, in which the textile sample is rubbed against a standard abrasive surface with a specified force. Please have a little look at this video showing the test in action. Rub Test Video. The standards are listed below –

- OD = Occasional domestic – 6,000 Rubs

- LD = Light domestic – 15,000 rubs

- GD = General domestic – 20,000 rubs

- HD = Heavy domestic – 25,000 rubs

- SD = Severe domestic/general contract – 30,000 rubs

- SC = Severe contract Abrasion performance – 40,000 rubs

An example of the certificate provided after a Faux Leather has been tested – Page 12 of this link – this is for the Seren Faux Leather which has a 250,000 rub test showing it is very good quality.

Hygiene – Another area which is a large concern for the facilities in which the faux is being used. The Antimicrobial Certificate and the Antifungal Certificate – Please see pages 1 and 2 on the link – This certificate is the answer to any of these concerns. Simply put, this certificate states that any microbes will not grow, or only grow by a minute amount over a certain amount of time. This is the certificate that Hospitals look for to ensure the highest levels of cleanliness and least threat of infections growing/spreading.

To conclude, knowing what you are looking for – as simple and slightly stupid as it sounds – this is essential to avoid getting bogged down in the detail. With the three key aspects explained, looking for these points will immediately shine a light on the Fabrics / Faux Leather, and show them as suitable for your needs or suggest you need to keep looking.

Written by Rory Simpson – Internal Sales Executive